Streamlining Automotive Parts Supply Chain

Parts Manufacturing

Parts Distribution Center

The Most Common Challenges in Automotive Parts Industry

With so many SKUs produced or distributed in the industry, there must be a tight control on managing every step of the operation to minimize wrong parts getting produced, distributed and assembled.

Based on our many encounters with Auto Parts players in the market, here are some of the most frequent issues or challenges.

Inefficient inventory handling often lead to overstocking or stock-outs, negatively impacting production, delivery schedules and raising costs.

Without regular cycle counts and control in-place, there will be constant fire-fighting and a lot of manual checkings.

Not enough visibility on warehouse space utilization combined with unpredictable demand will cause warehouse space overflow.

There needs to be a way to get real-time visibility to help with better decisions concerning utilization of storage space.

One way to speed up order fulfillment process is by streamlining the whole pick & pack flow.

There has to be a way for packing staff to keep his/her focus on the task on hand instead of always keep searching what to be packed.

Wrong or slow delivery will lead to low customer satisfaction level and financial losses if they need to re-arrange shipments because of the mistakes.

There is also heighten risk of bigger loss & spoilage of sensitive products because of the re-transit process.

Company reputation will be hit hard if defective products gets distributed and is not handled properly.

The products need to be hold while still in the internal factory environment and recall those that already get distributed out.

How Largo Can Address The Challenges

The Solutions

Largo WMS (Warehouse Management System) is the flagship product that provides end-to-end solution for managing a warehouse properly from the inventory, warehouse space to operators activities. It is definitely a powerful addition to your financial or ERP application.

Largo Manufacturing WIP (Work-In-Progress) is the solution for tracking real-time production progress in order to discover bottlenecks quickly and improve efficiency with its OEE indicator. It is designed to capture good and bad produce as well as recording downtimes.

Largo AMT (Asset Movement Tracking) is designed to track your pallets, plastic boxes, steel cages, etc that are used to contain your products. Have the real-time insights on the availability as well as where they are located, internally as well your customers’ locations.

Latest News

Find useful articles, news and update around barcode, RFID and warehouse operation here ...

-

Warehouse Management in Manufacturing Industry

Introduction Warehouse management in the manufacturing industry is a critical component of the overall production process. Efficient warehouse management ens

-

Existing Barcode vs New Barcode

We often come across question from our client “Can we use our existing barcode on the product in the warehouse” ? Well, the simple rule in the wa

-

Choosing the Right Mobile Computer for WMS

Mobile Computer or some call it PDT, HHT, RF, Handheld…is an integral part of warehouse management system implementation. This device will be used in a

-

COVID-19

As we all know, during this Covid-19 pandemic times, Jakarta and most major cities in Indonesia, has implemented a Circuit Breaker initiative which limits th

-

How long to implement a WMS System?

Implementing warehouse management system requires several steps to ensure its success. It’s not just the system as the system usually is ready to be de

-

Penggunaan Barcode di Gudang (Warehouse / Distribution Center)

Penggunaan barcode di sudah biasa kita temukan di produk-produk yang setiap hari kita gunakan, dari alat-alat rumah tangga, makanan, minuman sampai ke alat-a

-

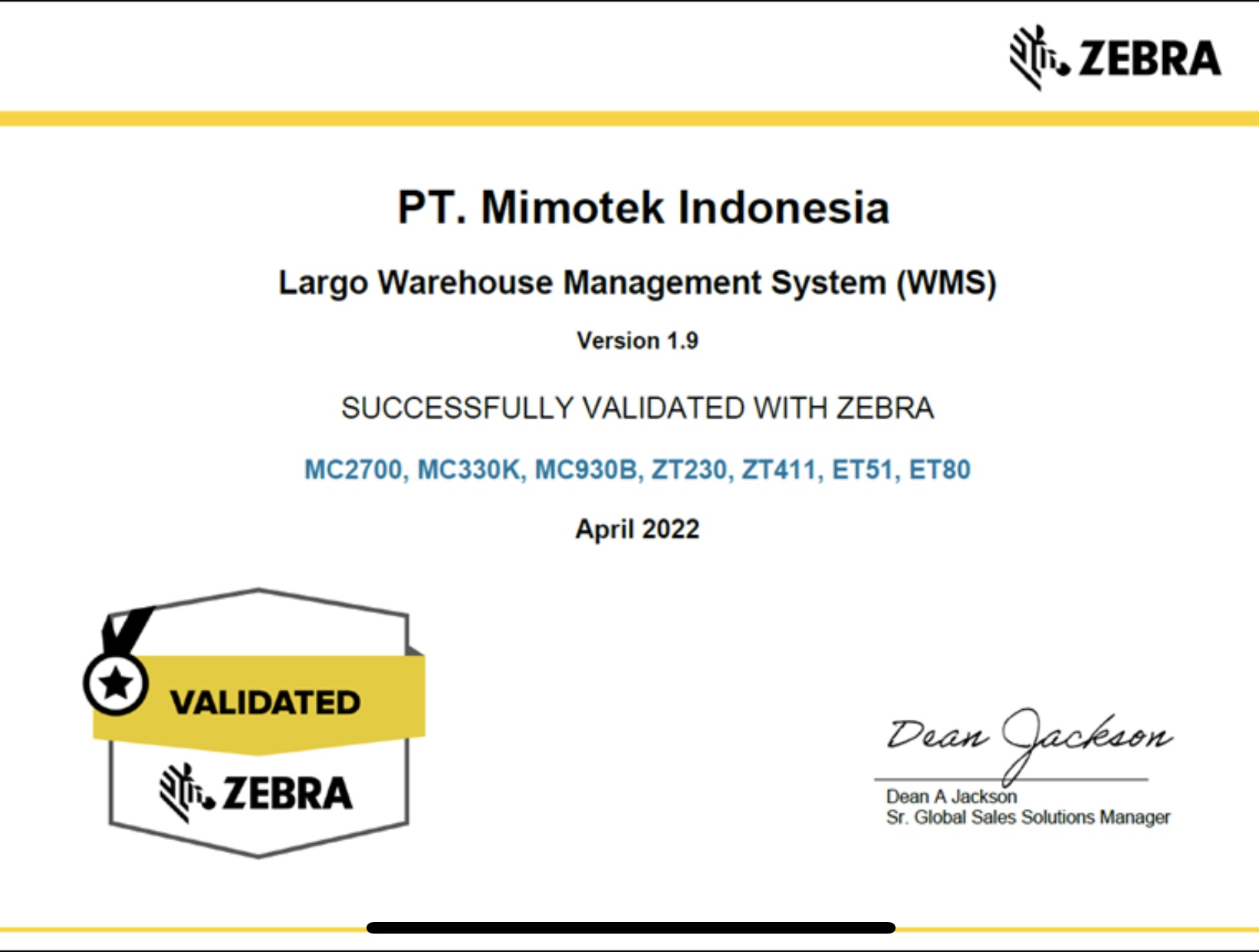

Largo WMS Achieves Zebra Technologies Validation

Largo WMS has been tested by Zebra’s Global Enablement Center to ensure the highest compatibility in delivering the best outcome in warehouse productivity

-

Warehouse Management in Retail

Introduction In the dynamic world of retail, efficient warehouse management is critical for ensuring timely delivery, inventory accuracy, and overall custome